Electroplating: Definition, Process, Advantages, & Applications

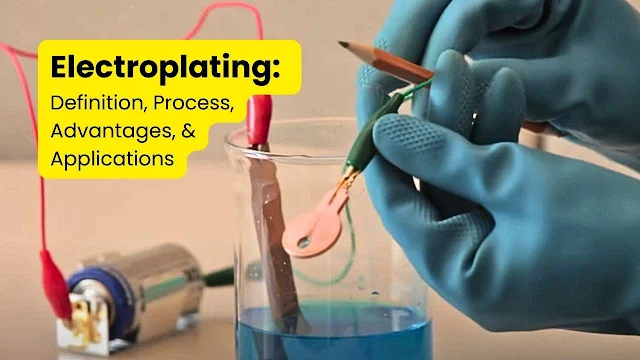

At its core, electroplating is a process that uses electrical current to deposit a thin layer of metal onto a conductive surface.

This process is commonly used in the manufacturing of a variety of products, ranging from jewelry to electronic components.

In this article, we'll explore the definition of electroplating, its process, advantages, and applications, and conclude by discussing its importance.

Definition of Electroplating

Electroplating is a process that involves the deposition of a thin layer of metal onto a conductive surface.

This is achieved by immersing the object to be plated (known as the substrate) into a solution containing ions of the metal to be deposited (known as the plating material).

An electrical current is then passed through the solution, causing the metal ions to be attracted to the surface of the substrate, resulting in the formation of a thin layer of metal on the surface.

Process of Electroplating

The process of electroplating involves several steps. The first step is the preparation of the substrate to be plated.

This involves cleaning the substrate to remove any dirt, grease, or other contaminants that may interfere with the plating process.

The substrate is then immersed into the plating solution, which contains the metal ions to be deposited.

An electrical current is then passed through the solution using an electrode made of the plating material. This causes the metal ions to be attracted to the surface of the substrate, forming a thin layer of metal on the surface.

The thickness of the deposited metal layer can be controlled by varying the duration of the plating process.

What is Electroplating Jewelry?

Electroplating jewelry is the process of applying a layer of metal, usually gold or silver, onto the surface of a base metal such as copper, brass, or nickel.

This process is done by immersing the base metal jewelry in a solution that contains ions of the metal to be plated, then passing an electrical current through the solution.

The metal ions in the solution will then attach themselves to the base metal, creating a thin layer of the desired metal on the jewelry's surface.

What is Nickel, Copper, Silver, and Zinc Electroplating?

Nickel, copper, silver, and zinc electroplating involve applying a thin layer of metal onto the surface of a base metal using an electrolytic process.

This process involves immersing the base metal in a solution containing ions of the metal to be plated, then passing an electric current through the solution.

This causes the metal ions to be attracted to the base metal, creating a thin layer of the desired metal on its surface.

Advantages of Nickel, Copper, Silver, and Zinc Electroplating

The primary advantage of electroplating with these metals is that it can improve the appearance and durability of the base metal. Each metal has unique benefits:

- Nickel electroplating can provide corrosion resistance, and wear resistance, and improve the base metal's hardness.

- Copper electroplating can enhance the base metal's conductivity and solderability.

- Silver electroplating can improve the base metal's conductivity, reflectivity, and resistance to tarnishing.

- Zinc electroplating can provide corrosion resistance and enhance the base metal's hardness.

Advantages of Electroplating

Electroplating has several advantages over other methods of coating or plating metals.

One of the main advantages is that it provides a very thin layer of metal that can be highly uniform and free of defects. This makes it an ideal method for coating complex shapes and surfaces.

Another advantage of electroplating is that it can be used to deposit a wide range of metals onto a variety of substrates. This includes metals such as gold, silver, copper, nickel, and chromium, among others.

Applications of Electroplating

Electroplating has a wide range of applications across many industries. In the automotive industry, electroplating is used to coat components such as wheels, trim, and emblems with a layer of shiny, corrosion-resistant metal.

In the electronics industry, electroplating is used to create conductive traces on circuit boards and plate connectors, and other components.

In the aerospace industry, electroplating is used to create corrosion-resistant coatings on aircraft parts.

In the medical industry, electroplating is used to create implants and other medical devices that are resistant to corrosion and wear.

Also, read:

- Liquid Coating: Definition, Types, and Applications

- Powder Coating: Definition, Process, and Applications

- Coating Process: Types, Applications, and Advantages

Conclusion

Electroplating is a process that has been used for over a century to deposit a thin layer of metal onto a conductive surface.

It is a versatile process that can be used to coat a wide range of metals onto a variety of substrates.

Electroplating has numerous advantages over other methods of coating or plating metals, including its ability to produce highly uniform and defect-free layers of metal.

The applications of electroplating are vast and span many industries, making it a crucial process in the manufacturing of many products.